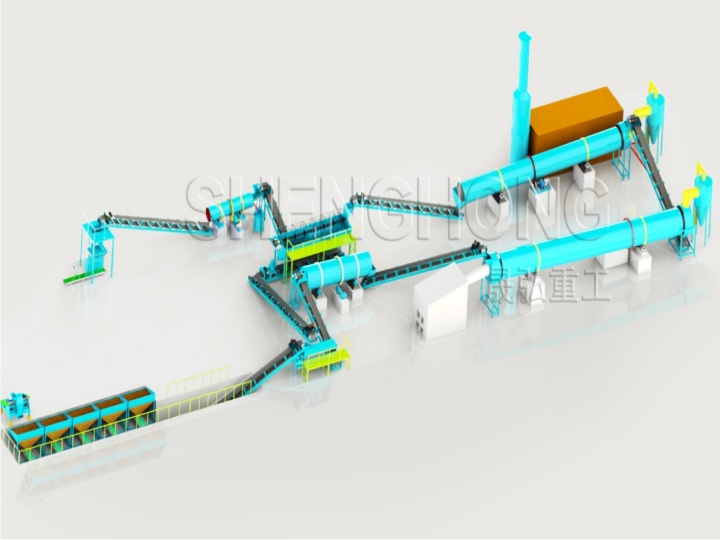

Compound fertilizer production line equipment process configuration

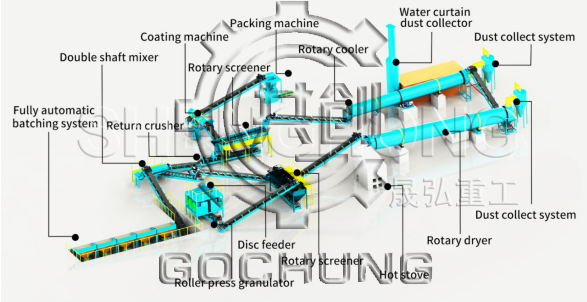

The process flow of compound fertilizer production line can usually be divided into: raw material ingredients, raw material mixing, raw material granulation, particle drying, particle cooling, particle grading, finished product coating, and final finished product packaging.

Compound fertilizer production line has less investment, quick effect and good economic benefit. Complete equipment flow layout is compact, scientific and reasonable, advanced technology. Energy saving, no three wastes discharge, stable operation, reliable operation and easy maintenance, wide adaptability of raw materials, suitable for compound fertilizer, medicine, chemical

The granulation of various raw materials such as work and feed has a high granulation rate. Can produce a variety of concentrations, a variety of types (including organic fertilizer, inorganic fertilizer, biological fertilizer, magnetic fertilizer, etc.) compound fertilizer. Especially thin, ammonium carbide series compound fertilizer granulation.

1. Raw material ingredients: urea, nitrate, chlorination, sulfur, ammonium phosphate (a hinge of phosphate, diammonium phosphate, heavy calcium, calcium), God chloride (potassium sulfate) and other raw materials are equipped in a certain proportion (according to market demand and soil detection junction around Fruit).

2, raw materials mixing: good raw materials mixing evenly to improve the overall uniform fertilizer efficiency content of fertilizer particles

3, raw material granulation: the evenly mixed raw materials into the granulator granulation machine (available drum granulator, can also choose extruded granulator).

4. Granule drying Dry: Send the particles made by the granulator to the dryer, dry the moisture contained in the particles, increase the strength of the particles, and facilitate storage.

5, particle cooling: the temperature of fertilizer particles after drying is too high, easy to caking, after cooling, easy to bag preservation, and transportation.

6. Particle grading: the cooled particles are graded, the non-grid particles are crushed and re-granulated, and the qualified products are screened out.

Technical parameter

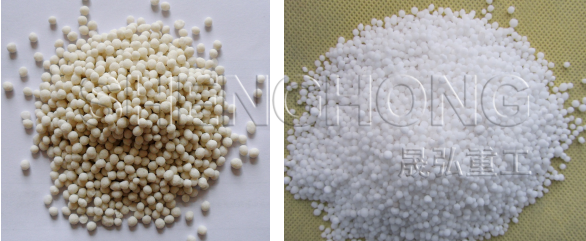

The nutrients of product particles are equal and balanced.Because it is chemically synthesized granulation, the nutrient content of granular fertilizer is the same as the label, and it can provide ammonia, phosphorus, potassium and other nutrients to crops at the same time in a certain proportion to ensure balanced crop growth.

Product physical properties Good product particle size distribution, 90% of the particle size in 2-4 mnm particles; The particle strength is high, the fluidity is good, it is not easy to break during transportation, storage and stacking, and the design integrates foreign advanced technology to further optimize the device design I can.

Leave your needs, we will get in touch with you as soon as possible!