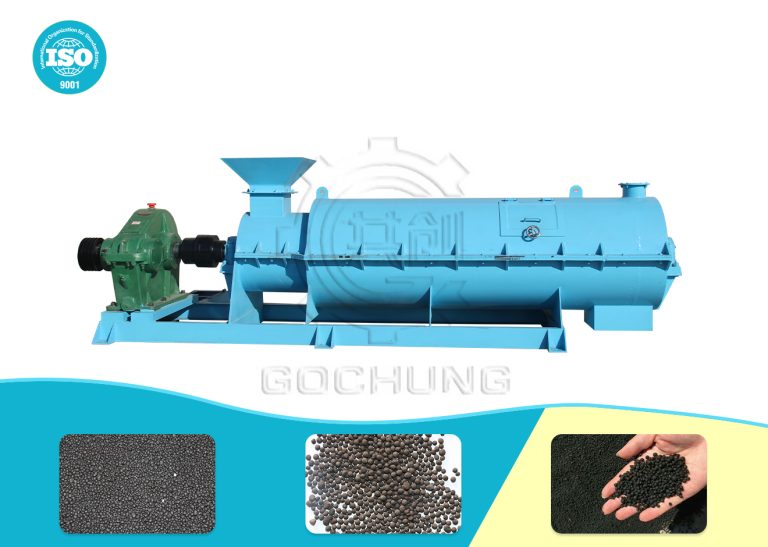

The machine adopts the method of internal stirring and external turning in the second stage of granulation, which not only meets the quality requirements of granulation but also solves the problem that some materials paste the wall due to excessive viscosity and humidity. The machine is mainly composed of a uniform feeding part, a primary granulation section, a secondary granulation section, a primary power part, a secondary stirring part, a secondary cylinder transmission part, a granulation bin part, a frame part, and so on.

| Model and Specifications | Motor power (kw) | Rotation speed (r/min) | Capacity (t/h) | Discharge particle size (mm) | Length × width × height (mm) | Equipment weight (kg) |

| SHZ2-80/120 | 45/18.5/11kw | 238/204/11.5 | 5-7 | 1-5 | 7400*1450*2100 | 5500 |

| SHZ2-100/150 | 75/22/11kw | 204/191/9.8 | 7-9 | 1-6 | 8500*2000*2100 | 8000 |

| SHZ2-120/180 | 90/37/18.5kw | 197/204/8 | 9-11 | 1-10 | 9350*2800*2500 | 10000 |

Applications and Functions The hydraulic roller granulator adopts dry roll pressing technology to compress the powder material with water content ≤8% into a sheet or…

Applications and Functions New organic fertilizer special granulator, used for livestock manure, urban sludge, and domestic waste processing organic fertilizer one of the granulation equipment.…

Applications and Functions The rotary drum granulator uses a special rubber liner or acid-resistant stainless steel liner to achieve automatic descaling and detumescence, eliminating the…

Horizontal Fermenter Use This equipment is suitable for various regions, including high humidity and high cold areas, and adopts a vertical, enclosed tank structure to…

Leave your needs, we will get in touch with you as soon as possible!