The Compound Fertilizer Production Line is a complete industrial solution designed for the large-scale manufacturing of NPK and blended compound fertilizers. It integrates raw material batching, mixing, granulation, drying, cooling, screening and packing into one efficient and stable production system. This line is suitable for producing compound fertilizers with different formulas and nutrient ratios to meet diverse market demands.

Raw Material Batching & Mixing

Multiple raw materials are accurately weighed and mixed to ensure uniform nutrient distribution.

Granulation System

According to product requirements, rotary drum granulator, extrusion granulator or disc granulator can be selected to form uniform fertilizer granules.

Drying & Cooling

Granules are dried to reduce moisture content and then cooled to improve strength and storage performance.

Screening & Recycling

Qualified granules are screened out, while oversized and undersized particles are returned to the granulation system.

Coating & Packing

Optional coating system improves anti-caking performance, followed by automatic weighing and packing.

Flexible Formula: Suitable for NPK and various compound fertilizer formulas

Stable Granulation: Uniform particle size and high granule strength

High Automation: Reduced labor cost and stable continuous operation

Energy Efficient: Optimized process design with low energy consumption

We provide a complete turnkey service including process design, equipment manufacturing, installation guidance, commissioning and operator training. Customized solutions are available based on your raw materials, capacity requirements and local conditions.

Professional fertilizer equipment manufacturer

Rich experience in compound fertilizer projects

Reliable quality and long service life

Comprehensive technical support and after-sales service

If you are planning to build or upgrade a compound fertilizer plant, our production line offers a reliable and cost-effective solution.

Applications and Functions The hydraulic roller granulator adopts dry roll pressing technology to compress the powder material with water content ≤8% into a sheet or…

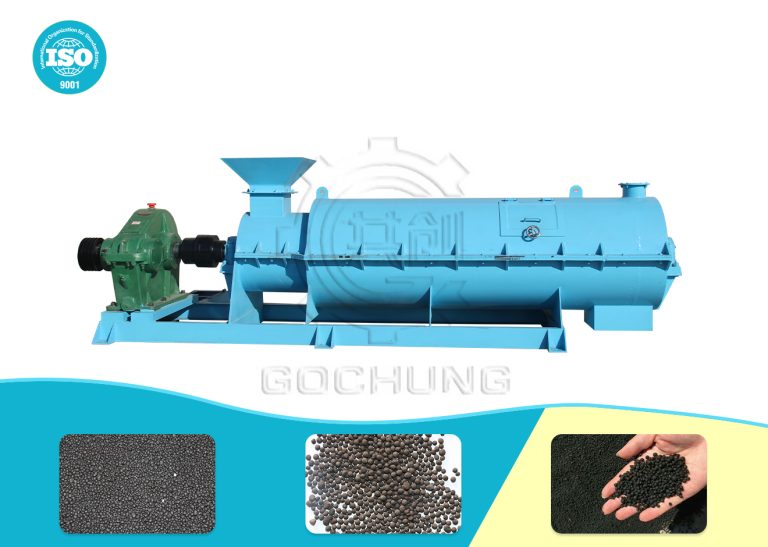

Applications and Functions New organic fertilizer special granulator, used for livestock manure, urban sludge, and domestic waste processing organic fertilizer one of the granulation equipment.…

Applications and Functions The rotary drum granulator uses a special rubber liner or acid-resistant stainless steel liner to achieve automatic descaling and detumescence, eliminating the…

Horizontal Fermenter Use This equipment is suitable for various regions, including high humidity and high cold areas, and adopts a vertical, enclosed tank structure to…

Leave your needs, we will get in touch with you as soon as possible!