The transfer granulator is one of the key equipments in the lime granulation, transfer granulator and crusher industry. It is suitable for hot and cold granulation and batch production of high, medium and low concentration compound fertilizers.

Product description:

The process flow of the compound fertilizer transfer granulation production line can usually be divided into: raw material batching, raw material mixing, raw material granulation, particle drying, particle cooling, particle classification, finished product coating, and final finished product packaging.

Performance features:

The transfer granulator production line is an efficient and energy-saving production equipment, suitable for granulating various raw materials such as compound fertilizer, medicine, chemical industry, and feed. It uses advanced ply transfer granulation technology to evenly stir the prepared raw materials and then feed them into the granulator. Through the high-speed rotation and shearing force of the ply transfer, the raw materials form uniform particles inside the machine. This kind of production line has the characteristics of high degree of automation, high production efficiency, uniform product particle size, and good particle quality. At the same time, the transfer granulator production line also has the advantages of simple operation and convenient maintenance. Operators only need simple training and guidance to quickly master the operating skills and ensure the stable operation of the production line.

Working principle:

Compound fertilizer production line process:

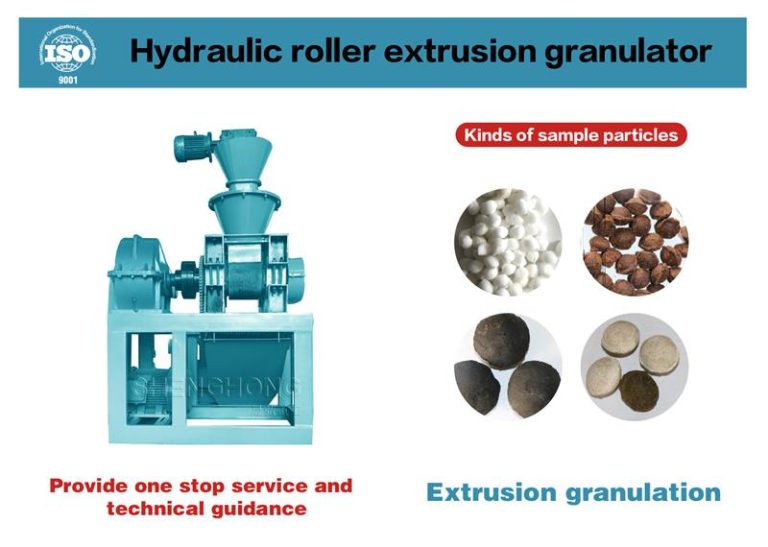

Applications and Functions The hydraulic roller granulator adopts dry roll pressing technology to compress the powder material with water content ≤8% into a sheet or…

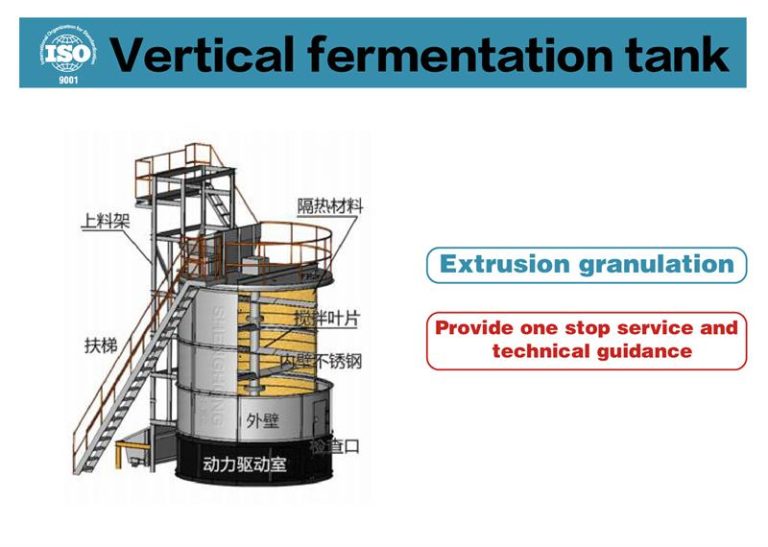

Applications and Functions New organic fertilizer special granulator, used for livestock manure, urban sludge, and domestic waste processing organic fertilizer one of the granulation equipment.…

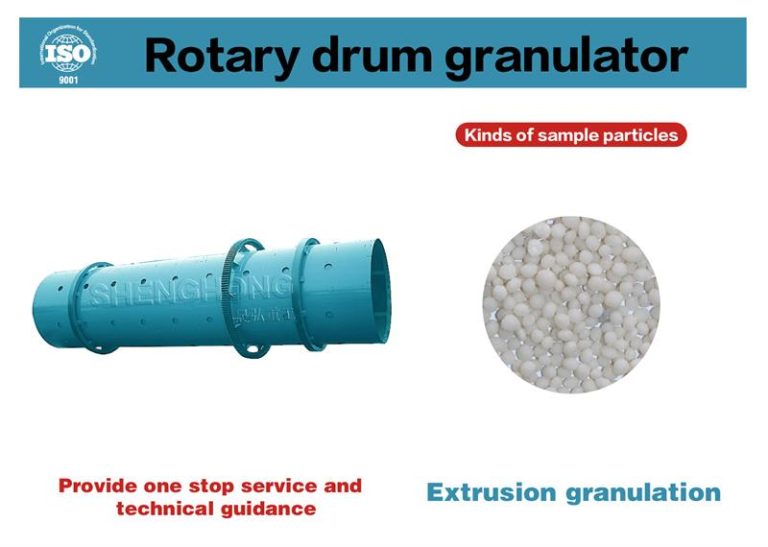

Applications and Functions The simplified machine adopts a special rubber plate lining or acid-resistant stainless steel lining plate, which realizes automatic scar removal and tumor…

Horizontal Fermenter Use The horizontal fermenter is suitable for the treatment of different feces, carcasses, kitchen waste, domestic sewage, and silt. As long as the…

Leave your needs, we will get in touch with you as soon as possible!