Organic fertilizer production lines are usually used to process different fermented organic matter into bio-organic fertilizer. Using a one-step molding process, livestock and poultry manure and agricultural waste are used as the main raw materials for recycling, which not only creates economic benefits for the enterprise, but also makes a huge contribution to human environmental protection.

Product description:

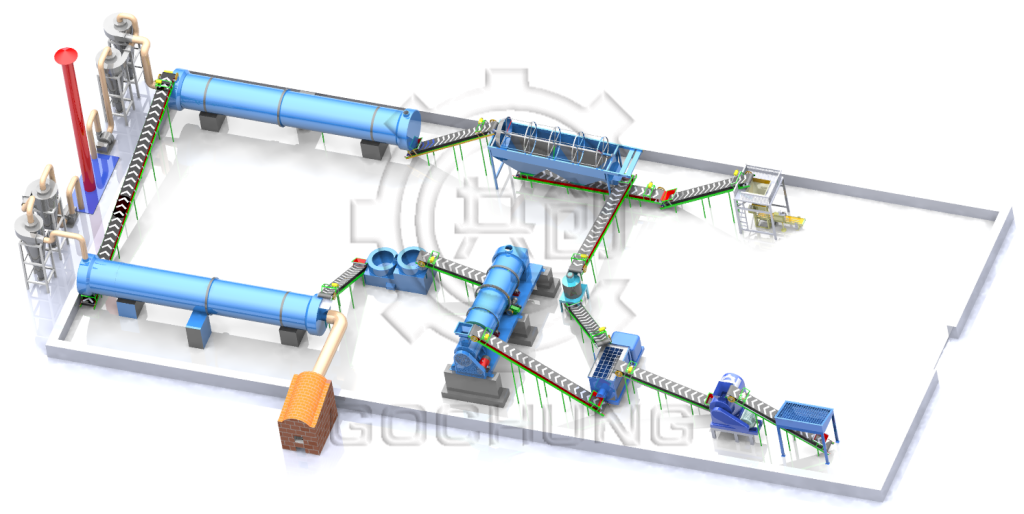

With the rapid development of the livestock and poultry breeding industry, a large amount of feces and sewage are produced. The harmful elements in these feces seriously exceed the standard and are difficult to be treated by the traditional method of returning to the field. In response to this situation, our company has developed a high-efficiency solid-liquid decomposition method. It is an organic fertilizer production line with sterilization and deodorization technology as the core, integrating high-efficiency feces fermentation, raw material mixing, granule processing, drying, packaging and other fertilizer production equipment and processes.

Performance features:

With its high efficiency, environmental protection, flexibility and reliability, the organic fertilizer production line is a kind of equipment specially used for the production of organic fertilizers. The production line is highly efficient and can greatly improve the production efficiency of organic fertilizers. Through automated production processes, the tedious manual operations are reduced, thereby improving production efficiency. The organic fertilizer production line is environmentally friendly and can reduce the impact on the environment. In the production process, environmentally friendly materials and processes are used, making the organic fertilizer produced more environmentally friendly and safer. And it is also flexible and can be adjusted and optimized according to different production needs. Whether it is production scale, raw material type or fertilizer formula, the production line can be adjusted to meet different needs.

Organic fertilizer production line equipment classification:

Applications and Functions The hydraulic roller granulator adopts dry roll pressing technology to compress the powder material with water content ≤8% into a sheet or…

Applications and Functions New organic fertilizer special granulator, used for livestock manure, urban sludge, and domestic waste processing organic fertilizer one of the granulation equipment.…

Applications and Functions The simplified machine adopts a special rubber plate lining or acid-resistant stainless steel lining plate, which realizes automatic scar removal and tumor…

Horizontal Fermenter Use The horizontal fermenter is suitable for the treatment of different feces, carcasses, kitchen waste, domestic sewage, and silt. As long as the…

Leave your needs, we will get in touch with you as soon as possible!