BB fertilizer is dry mixed fertilizer. It is made of single fertilizer, compound fertilizer or organic fertilizer through simple mechanical mixing. No obvious chemical reaction occurs during the mixing process.

Performance features:

Its performance characteristics are mainly reflected in the following aspects: First, the equipment adopts advanced production processes and technologies, which can achieve continuous and stable production and improve production efficiency; secondly, the equipment has an intelligent control system that can automatically adjust various items. parameters to ensure stable and reliable product quality; in addition, the equipment also has the characteristics of energy saving and environmental protection, can effectively reduce energy consumption and emissions, and meets modern environmental protection requirements.

Working principle:

BB fertilizer production line equipment. It uses advanced production technology and technology to mix a variety of nutrients in a certain proportion to make a uniform blended fertilizer. First, the raw material storage system will store various raw materials such as nitrogen, phosphorus, potassium, etc. separately, and accurately measure them through metering equipment. Then, the mixing system will send the measured raw materials into the mixer for thorough mixing. The mixed materials will pass through the conveying system and enter the granulation system. In the granulation system, materials undergo processes such as extrusion and cutting to form particles of a certain size. The granular material then enters the drying system where excess moisture is removed through hot air drying. The dried granular materials will enter the cooling system for cooling. Finally, the cooled BB fertilizer particles will pass through the screening system for classification and screening to obtain finished products that meet the requirements. Throughout the production process, the BB fertilizer production line is also equipped with a dust removal system to control dust emissions and protect the environment.

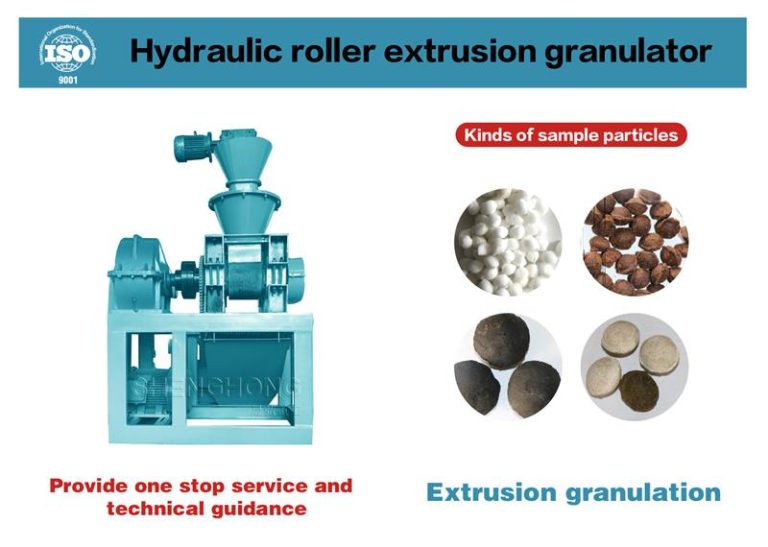

Applications and Functions The hydraulic roller granulator adopts dry roll pressing technology to compress the powder material with water content ≤8% into a sheet or…

Applications and Functions New organic fertilizer special granulator, used for livestock manure, urban sludge, and domestic waste processing organic fertilizer one of the granulation equipment.…

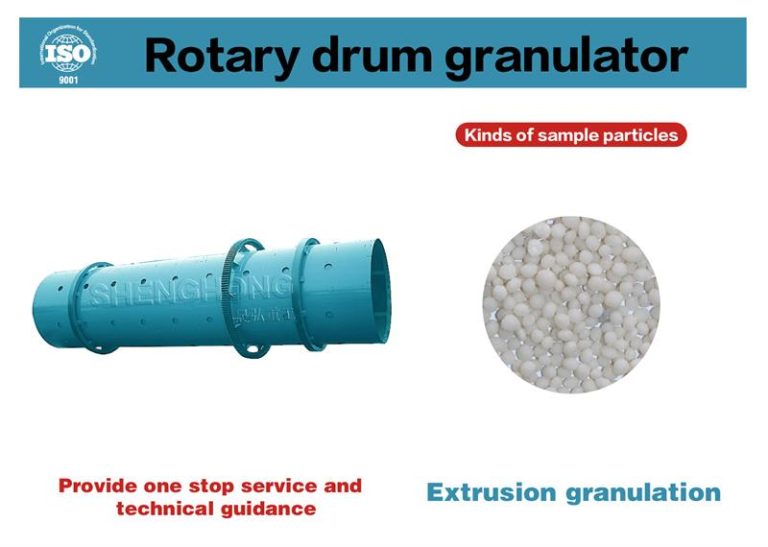

Applications and Functions The simplified machine adopts a special rubber plate lining or acid-resistant stainless steel lining plate, which realizes automatic scar removal and tumor…

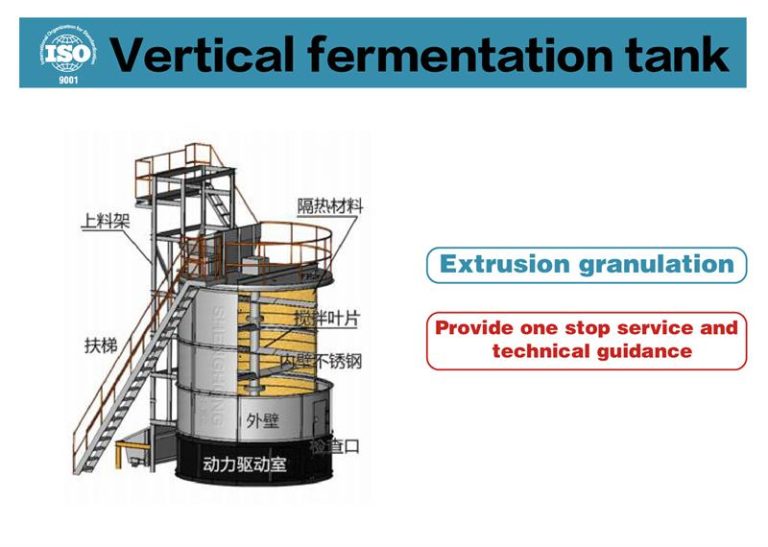

Horizontal Fermenter Use The horizontal fermenter is suitable for the treatment of different feces, carcasses, kitchen waste, domestic sewage, and silt. As long as the…

Leave your needs, we will get in touch with you as soon as possible!