Description

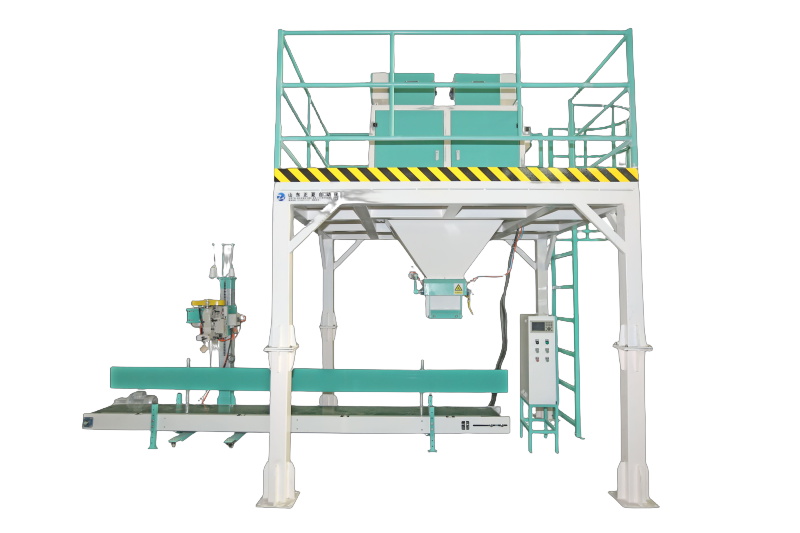

This fertilizer granulator is designed and manufactured according to the requirements of compound fertilizer plants and fertilizer dispensers, with a productivity of 10,000-100,000 tons. Lift tank feeding and mixer are used to load materials. The main body adopts forward or reverse movement, and uses a built-in screw structure and a three-dimensional structure to mix and convey materials.

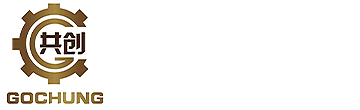

This production line is mainly composed of

1. Ingredients system

2. Belt conveyor

3. BB fertilizer mixer

4. Packaging scale composition

Advantages of BB fertilizer production line:

- The single-bag mixing method is adopted, which makes it easy to control the materials in each bag and has high mixing uniformity.

- The spiral section of the mixing section is reasonably designed, mixing evenly, and the materials can move in and out quickly.

- Computerized automatic batching/mixing/packaging, using twisting cage feeding method, small footprint, less labor, and less investment.

- The entire device is made of stainless steel, which is corrosion-resistant and has a long service life.

Features of BB fertilizer production line

- Adapt to uniform mixing of solid powder particles

- Granular raw materials cannot be broken during the mixing process.

- Productivity 1~20t/h

- The mixing uniformity of materials meets the technical requirements

- Little environmental pollution and meets environmental requirements

- The overall layout is beautiful, compact, and easy to operate and maintain.

- The equipment has low cost and good economic performance.